WIRE ROPES

CONSTRUCTION

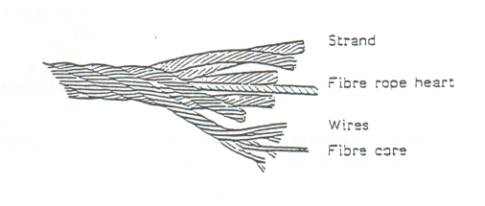

A wire rope is constructed of a number of small diameter wires which extend continuously for the entire length of the rope. These wires are laid up around a central core into strands, the strands are also laid up around a central core (or heart) to form the rope.

Usually the wires forming the strands are laid up left handed and the strands are laid up right handed. The individual wires are preformed during manufacture to give the exact spiral they will take up in the completed rope. thus the wires and strands lie in their true positions free from internal stress and will not spring out of place should the rope be cut.

The core of the strands and rope may be made of natural or man-made fibre or of wire.

The function of a fibre core is to act as a cushion into which the strands bed and to absorb the lubricant with which the rope is dressed to that when the rope is stretched the oil is squeezed between the wires and thus reducing friction. A fibre core will also make the rope more flexible and easier to handle by hand.

Wire corded ropes are used where severe working conditions apply, for example crane wires and powdered mooring winch wires where the lower turns on the drum are subjected to severe crushing loads by the upper turns. The wire core gives better support for the outer strands.

LAY

As with fibre ropes the direction in which the strands are made up is described as Right Hand or Left Hand laid.

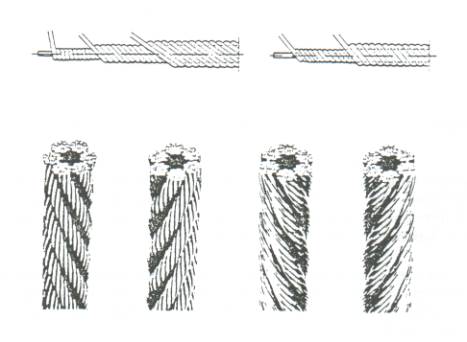

In addition the lay of the strands may be described as Ordinary Lay or Lang's Lay. Although Lang's Lay has superior fatigue and wear properties compared with ordinary lay it is not suitable for mooring ropes since both ends must be secured and it tends to king when handled manually. It is used for cranes because it does not rotate under load due to the outer layer of wires in the strand being twisted in the same direction as the lay of the strands in the rope.

Ordinary Lay wires are suitable for moorings and derrick wires. The outer layer of wires in the strands are twisted in the opposite direction to the lay of the strands in the rope.

The lay of the wires in the strands may be either Cross Lay or Equal Lay.

Cross Lay ropes are not commonly used in marine work now. See fig. In this construction the wires cross over each other and there is considerable chafe between the wires when the rope is repeatedly put under tension and relaxed.

Equal Lay construction. See fig. Each wire lies alongside the adjacent ones and thus external wear is reduced, it is 14% stronger than cross lay construction.

DESCRIPTION

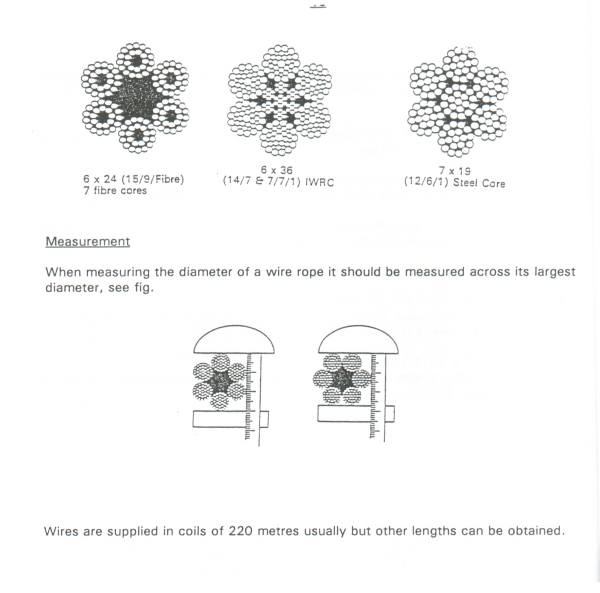

A full description of a steel wire rope includes the diameter and construction of the rope followed by the construction of each strand in brackets followed by the lay details.

e.g. 24mm 6 x 24 (15/9/Fibre) Fibre Main core Right Hand Equal Ordinary Lay galvanised steel wire rope.

This would indicate a 24mm diameter rope consisting of 6 strands around a fibre core. Each strand having 24 wires made up of 9 central wires overlaid by 15 wires. See fig.

Most wire ropes are made of galvanised wires, i.e. steel wire which has been coated with zinc, to protect the steel from corrosion.

A rope with a wire heart could be described as:-

24mm 6 x 36 (14/7 and 7/7/1) IWRC

i.e. 24mm diameter, 6 strands each of 14 wires around 7 around 7 around 7 around 1 wire.

Independent Wire Rope Core of 24mm 7x 19 (12/6/1)

i.e. 24mm diameter 7 strands of 19 wires, 1 of the strands being the core of the rope.

Care of Wire Ropes

Because wire ropes are made from steel care must be taken to prevent corrosion. As already stated the manufacturer coats the wires with zinc. this will, in the course of time, wear away and be consumed by electrolytic action in protecting the steel. Therefore to extend the life of the rope as much as possible the wire should be periodically coated with a patent wire rope dressing. This will keep moisture off the steel and help to lubricate the wires to reduce the wear between the wires when the rope is under tension. The frequency of this dressing will depend on the degree of exposure to which the wire is subjected.

When handling wire ropes, because of their comparative lack of flexibility compared with fibre ropes; more care is required. Wire ropes can be seriously damaged by kinking, crippling and flattening.

KINKING

Any loop in a wire can all too easily be pulled into a kink which will permanently damage the rope. If a kink is seen to develop it should be removed as shown in fig.

CRIPPLING

If a wire rope is bent at too acute an angle or led over

a sharp edge it will be seriously damaged by distortion

of its strands. A rope so led is said to form a "bad

rip" and results in the rope being crippled.

To prevent crippling a wire should never be led around any object whose diameter is less than 15 times the rope's diameter and for running rigging the diameter of the sheaves in the blocks should be at least 20 times the rope's diameter

FLATTENING

If a wire rope is flattened the strands will be distorted and the rope seriously damaged. This can occur if the wire is incorrectly led onto a winch barrel or the incorrect type of wire is used on a winch.

The first turn of wire has been wound incorrectly on the drum. It is underneath the succeeding turn which will flatten the first turn. The turns should be laid on to the drum evenly starting from one end working towards the other.

Coiling and Uncoiling

New wire ropes are supplied in coils, either on cable

drums or in machine wound coils. They must be uncoiled

correctly or kinks will quickly develop, A small coil can

be roiled along the deck but large coils must be placed

on a turn-table which has two strong pieces of wood

crosswise on top of the coil to prevent the turns from

springing off.

When the coil is on the turn-table the stops can be cut and the rope hauled off the coil.

When coiling down a length of wire rope the end must be free to rotate to that the turns placed in the wire by the action of coiling down can work their way out of the wire. Where this is impossible because of the length of the wire an alternative is to use left handed loops, called "Frenchmen" in the coil. Frenchmen serve to counteract the turns put in by coiling down right handed. Right hand lay ropes are always coiled down right handed.

When uncoiling a wire rope stand clear as the rope is hauled off the coil because "Frenchmen" are liable to Jump up. Where possible two seamen should work together with one man keeping the coil under control.

INSPECTION

A wire rope should be inspected before use to detect any of the above conditions so that its suitability (strength) may be estimated. Also to determine the state of the protective dressing. The "Docks Regulations 1934" require that a wire rope be condemned if in a length of 8 times its diameter, more than 10% of the visible wires have been broken or the rope shows signs of excessive wear, corrosion or other defect which in the opinion of the person who inspects it, renders it unfit for use.

The strength of wire ropes may be assessed using the following formulae, where D is the diameter in millimetres.

Breaking Strength

6x12 = 15D25OO tonnes

6 x 24 = 20D2/500 tonnes

6 x 37 = 21D2/500 tonnes

The Safe Working Load (SWL) is found by allowing a safety factor of six for general marine work - i.e. SWL = Breaking Strength/6.